Polycarbonate – PC

Polycarbonates (PC) are polyesters consisting of phenol groups in the main chain. In addition, they are transparent, and this transparency can be as high as 90%. This is because the crystallinity is low, which means that the chain is almost amorphous. The explanation is due to the fact that there are benzene groups in the main chain, so it is very rigid, preventing the molecule from being flexible.

Another characteristic is the high mechanical resistance to traction and impact. Polycarbonates also have good electrical properties and hardness up to a temperature of 140°C.

They are inert, and the molecular structure is quite symmetrical. Although they are separated by aromatic hydrocarbons, the groups are polar.

This type of material has a very high resistance to flame and weathering. The density of the material is 1.20. Polycarbonates also have another advantage: they are much lighter than other materials such as glass and plastic.

Polycarbonate Applications:

This material is used as a raw material in the production of sheets to be used in place of glass in specific conditions, such as in airplanes (use in windows, because the material must be very resistant), in sunroofs of buildings, etc. Another application: manufacturing of sunglasses and production of CDs and DVDs.

Because they are easily molded at high temperatures, polycarbonates have the property of reuse. That is, they are recyclable. In electronic and electrical engineering, it is widely used in the production of relay housings, timing switches, and even some types of batteries, among others. This is because polycarbonate is a very good insulator (both thermal and electrical), and besides having great durability, it has high fire resistance.

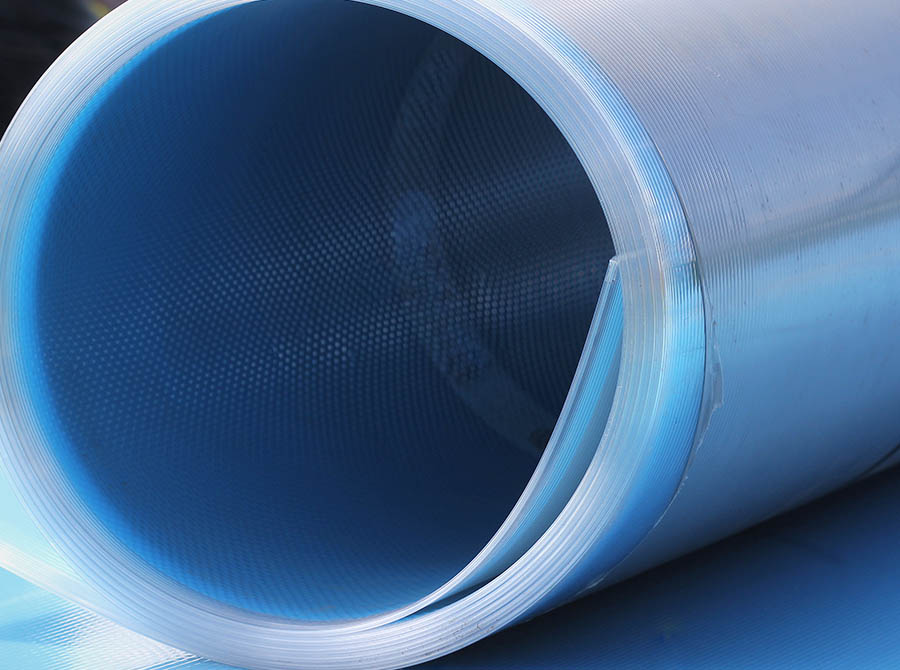

Polycarbonate is used in the production of spiral-shaped wires, because polycarbonate is a good insulator. It is tensile resistant, does not deform, does not lose its thermal stability, and resists deterioration caused by oxygen very well.

The films produced with this material and with a high molecular weight are used in the manufacture of capacitors. They are used in the manufacture of car parts, gymnasium windows, kiosks, applications in photography and applications in houses, in the production of pots, forks, knives, glasses, fruit bowls, etc.